Dry Fog Dust Suppression System

Introduction to Dust Suppression

Dry fog systems have emerged as a highly effective solution for dust suppression. Utilizing advanced dry fog technology, these systems use compressed air and water to create micron sized droplets. When these like sized droplets and dust particles collide, agglomeration occurs, forming larger particles that are too heavy to remain suspended in the air and thus fall back into the process by gravity. This process ensures that dust is controlled at the source, reducing the spread of airborne dust and improving overall air quality.

By integrating dry fog systems into dust-generating processes, industries can significantly reduce the risks associated with dust exposure, enhance operational efficiency, and maintain compliance with health and safety standards. The ability to create micron sized droplets that effectively bind with dust particles makes dry fog technology a preferred choice for modern dust suppression systems.

What is Dry Fog?

To achieve agglomeration at the dust source, equal amounts of like sized particles of water droplets and dust particles must exist and they must be contained in an enclosed area.

At the treatment point, fog droplets are used to blanket the dust source and prevent the dust particles from becoming airborne.

Learn more about the key concepts of Dry Fog on the Dust Control Theory page.

Advantages

- Highly efficient and effective at reducing fugitive dust and suppressing respirable dust

- Low water use

- No chemicals

- Minimises wetting and overall moisture content of the material

- Returns useable material to the product stream

- Ease of installation

- Low maintenance

- Flexible system configuration

Applications of Dry Fogging

Dry fogging is a versatile dust suppression solution with applications across a wide range of industries. It is particularly effective at suppressing dust at conveyor transfer points, where bulk material movement often generates significant dust emissions. Other common applications include trippers, reclaimers, crushers, screens, truck dumps, railcar loading and unloading, ship loaders and unloaders, and ash silo discharge chutes.One of the key advantages of dry fogging is its ability to suppress dust while minimizing the moisture content added to bulk materials. This assists in preventing clogging of equipment due to sticky material, helps prevent water damage and reduces the risk of equipment corrosion, ensuring the longevity and reliability of critical machinery.

Why DSI Dry Fog?

DSI's low flow, ultrasonic nozzles create fog droplets 1-10μm in size which easily agglomerate to dust particles as small as PM2.5 and PM10. These ultra-fine fog droplets attach to similar size dust particles and drop them back into the process. As the particles agglomerate they also join and suppress the larger dust particles as well. When compared to alternative technologies, DSI Dry Fog’s ultra-fine atomization can agglomerate to the widest range of particle sizes due to its small droplet size.Wet Earth uses the DSI Dry Fog System because it is a robust, proven solution that has been used since 1997 in over 50 countries.

The DSI nozzles produce the finest droplets and have large throw distances compared to similar solutions from other vendors. The DSI nozzle enclosures provide robust protection to the nozzles and their complete solution simplifies installation. DSI nozzles are manufactured in the US and solutions are manufactured in a combination of the US and Australia.

The solution design utilises the experience of DSI’s engineers based in the US (who have designed thousands of systems) which ensure you get the best possible performance for your system.

Wet Earth DSI Dry Fog installations in Australia include:

- Whitehaven Daunia

- CS Energy Callide Power Station

- Jellingbah Coal

- Ora Banda Mining

- Peabody Wambo

- Fulton Hogan Eastern Creek

Other DSI Dry Fog installations in Australia include:

- BHP Port Hedland Operations

- Citic Pacific Sino Iron

- FMG Cloudbreak and Christmas Creek

- Newcrest Cadia And Telfer Operations

- Newmont Boddington Gold

- First Quantum Ravensthorpe

- Glencore George Fisher, Mt Isa, Hail Creek and Townsville Port

What about High Pressure Misting ?

In contrast, dry fog systems use compressed air and water to create smaller sized droplets (3 to 6 micron) that are much better suited for binding with fine dust particles. This allows dry fog to achieve superior dust suppression, particularly for respirable dust that can travel offsite or be inhaled by workers. Additionally, dry fog systems require less water than high pressure misting systems to achieve the same dust suppression performance due to the larger surface area of the smaller droplets.

By choosing dry fogging over high pressure misting, industries benefit from improved dust control, reduced water usage, and lower operational costs, all while ensuring compliance with stringent health and safety regulations.

The DSI Dry Fog System

DSI Dry Fog systems allow for flexible configuration with pre-assembled modular components. The type of application, type of bulk material creating dust, and operating environments are considered when customizing your system.

Housed in protective enclosures, we supply

complete systems comprised of electrical controls, filtration, flow regulation,

supply lines and nozzle mounts. If required, we can supply all necessary

ancillary items including air compressors, air receiver stations, pumps, and

self-cleaning secondary filtration systems.

Key system components are described in more detail below.

DSI Dry Fog Nozzles

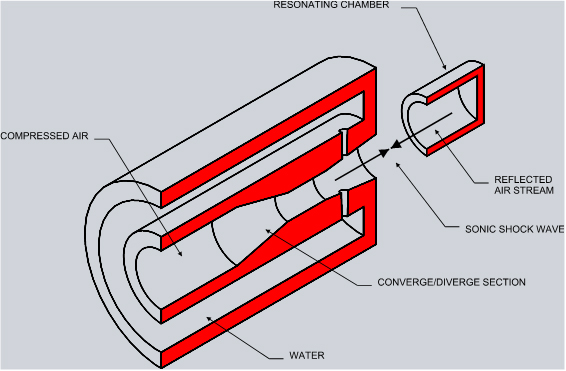

DSI Dry Fog nozzles use a combination of focused compressed

air and water and an external resonator to create an ultrasonic shock on the

water particles to break them into a fine fog. They are commonly referred to as

air atomising nozzles. The technology is illustrated in the following diagram.

The inlet water and air

pressures for air atomising nozzles are relatively low (1 bar water and 5 bar

air). It is possible to adjust these pressures to change the water droplet

particle size and allow the fog to be 'drier' or 'wetter' depending on the

material, application or other factors.

The DSI Dry Fog nozzles create droplets with a very small droplet size and a relatively low velocity which makes them ideal for capturing PM10 dust particles.

The DSI Dry Fog nozzle is the key element of the system converting the water into a dust suppressing fog. The nozzles are stainless steel and manufactured to exacting standards to ensure their performance. There are other ultrasonic air atomising nozzles available on the market, but most droplet sizes are well above the 1 to 10 micron size droplets that the DSI nozzles produce.

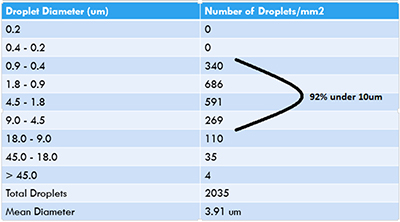

The following table provides an example of the droplet size distribution for the DSN-3 nozzle.

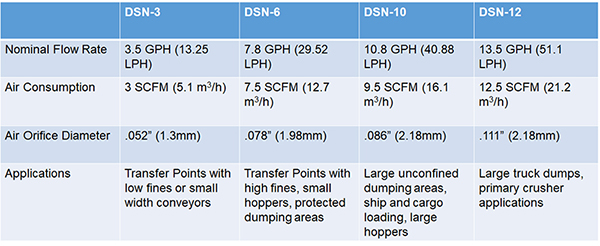

The following table lists the specifications for the range of DSI Dry Fog nozzles.

Universal Fogger Assembly

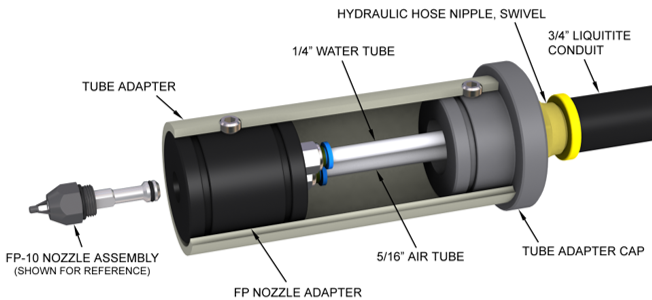

Ultrasonic air atomising nozzles are prone to damage due to

the thin wire that supports the resonator. The Universal Fogger Assembly

addresses this with the use of a robust enclosure for the nozzle as shown

below. The enclosure also combines air and water lines into a single

flexible hose from the supply enclosure.

Fogger Mounts

It is important to be able to install the nozzles so that they can be positioned and angled for optimum coverage. There are a range of Fogger Mounts that provide robust methods to position the Foggers so they are secure and easy to access.

Ball and Socket Mount

The Ball and Socket Mount allows the Fogger to be fitted

from the outside of transfer points and angled to provide best dust

suppression performance.

Angle Bracket Mount

The Angle Bracket Mount allows the Fogger to be connected to

most surfaces and allow the Fogger to be angled to the direction which provides best performance.

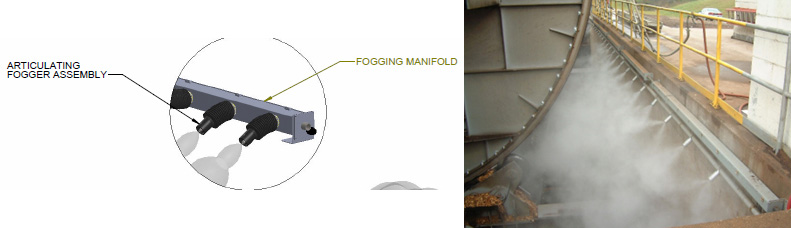

Fogging Manifolds

The Fogging Manifolds provide a multi-directional stainless-steel housing for the fog nozzles which are then connected through one conduit to the Multi-Function Modules. The Fogging Manifolds have the following features:

- Heavy duty steel casing

- Easily mounted

- Factory fitted internal manifolding, single connection to Multi-Function Modules for easy installation

- Unidirectional nozzle mounts allow adjustment of the fog direction to where it is needed

Fogging Solution Modules

There are a range of modules that can be included in a DSI Dry Fog solution which depend on the project size and layout.

The key functions of these modules are:

- Filtration – typically multiple levels with self-cleaning function

- Pressure control of water and air – to ensure the ideal performance of the atomising nozzles.

- Electronic control – interface to other site systems

- Distribution of the water and air to each nozzle