Wind Fence vs Dust Fence

Wet Earth offers both Wind Fence and Dust Fence solutions. These may look similar and in some cases similar technologies can be used, but there significant differences that are discussed below.

What is a Wind Fence

A Wind Fence is designed to installed upwind of the dust source to reduce the speed of the wind to a level which significantly reduces dust lifting off the surface. This reduction in wind also makes other dust control solutions such as Fogging Systems and Stockpile Spray Systems much more effective.

A Wind Fence is simply a wall of fabric which lets a portion (typically around 10% to 25%) of the wind to pass through. Wind Fences can be made from mesh material or strand material as it only needs to slow the wind speed.

A Wind Fence position and height is designed to ensure that the wind is minimised across the area likely to release dust.

What is a Dust Fence

A Dust Fence is a wall of material designed to capture dust that is blown into them. They are positioned down wind or enclosing the source of dust.

Dust Fences are made from a mesh material that is designed to capture dust. In many cases this will also use static attraction or curved material to increase the capture capability.

As Dust Fences capture dust they need to be cleaned or be self cleaning.

As Dust Fences are still are fabric that allows a portion of the wind to pass through they also function as a wind fence which is very useful in most applications.

Wind Fence vs Dust Fence Material

The major difference between the two systems is the material. This determines how they work, how long they last and how they are installed.

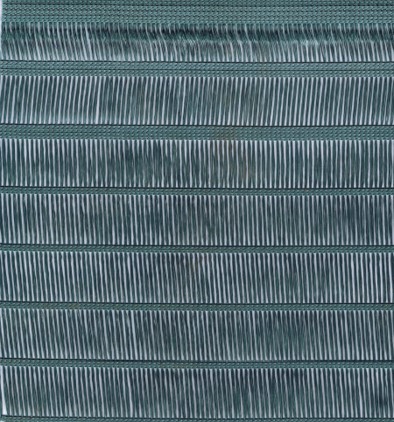

Long Strand Wind Fence Material

Long strand material has long thin filaments that reduce the wind speed without capturing dust. The long strands prevent dust particles getting caught in material and those that do get caught are easily release by the wind moving the strands.

The long strand material is made from polyester. Polyester is a very stronger, high UV resistant material that is used for applications such as tie-down straps for truck loads. Wind Fence materials made from it typically have a 15 year lifespan.

The long strand wind fence materials are designed to be installed taught to prevent saging or rubbing which reduces the material lifespan. For example each length (0.9m to 1.5m wide) of Dust Tamer material needs to be tensioned to 250kg as it is secured to the supporting structure.

The requirement for the material to be tensioned means that the material needs to be secured directly to the support structures which limits the spacing between the supports to about 8m. The requirement to be secured directly to the support structure also mean the installation of the material is much slower and hence costly.

Mesh Wind Fence / Dust Fence Material

The mesh structure allows the material to both reduce wind speed and to capture the dust particles. As a result this material is used for both Wind Fences and Dust Fences.

The major negative of the mesh material is that it requires cleaning. It is important to note that not all dust that gets captured by a Dust Fence needs to be cleaned out as the action of the wind does assist with self cleaning. The way Dust Fence material is installed can also determines its ability to self clean - a taught material is less likely to release dust than a loose installation that has some ability to stretch and move in the wind. It should be noted that a loose material is likely to have a shorter lifespan due to the continual stretching, contracting and rubbing.

Mesh Wind fences are made from either woven Polypropylene or Polyethylene. This is not as strong or long lasting as the Polyester used for Wind Fences. As a result the mesh material needs to be replaced about every 5 years.

Cleaning of the Dust Fence material is important because a clogged dust fences also has a reduced capability to capture dust. If a material is allowed to clog up then the fence behaves more like a solid structure. Solid fences create turbulence due to the high pressure on the up wind side and the low pressure on the down wind side. This turbulence can cause significant amounts of dust lift off. A clogged fence also changes the requirements of the structure because more wind force is imparted on a clogged material vs unclogged material.

The mesh Wind Fence / Dust Fence is secured to the structure using cables. The mesh is hung from these cables and secured on the sides and bottom with clips which release in high winds. This release means that the supporting structures only need to be designed for the wind speed that the clips release (typically 90-120km/hr). This means that the Wind Fences / Dust Fences using a mesh material do not require the same strength structural supports (and hence cost) as those using the long strand material.

The cable support also allows the mesh wind fences to have much greater spacing between supports (up to 30m) and have much higher fence heights (up to 55m) than the long strand material fences.

More information on Wind Fences and Dust Fences

Use the following links for more information on Wind Fences or Dust Fences. If you have a particular dust control application you would like to discuss or would like more information then please call us on +61 2 6062 3300 or send an email to sales@wetearth.com.au.